Operating Instructions and Environmental Benefits of Our Plastic Dryers

Plastic Dehumidifiering Dryers General Usage Guidelines:

- Position the hopper dryer on a stable, level surface to ensure operational stability.

- Connect the power supply in accordance with the specified electrical requirements.

- Load the plastic granules into the designated drying hopper.

- Utilize the control system to program the desired drying temperature and processing duration.

- For models incorporating dehumidifying capabilities, verify proper connection and functionality of the desiccant rotor.

- Initiate the drying cycle and monitor the process to ensure optimal performance.

- Upon completion of the drying cycle, the processed dry plastic is ready for subsequent manufacturing stages.

Environmental Responsibility:

Our energy-saving dryer designs contribute to a reduced environmental impact by minimizing overall energy consumption. Furthermore, the efficient removal of moisture in plastic minimizes the incidence of manufacturing defects, thereby reducing material waste and promoting resource efficiency.

Customer Feedback aboutPlastic Dryers:

“Since implementing the TOPDA honeycomb dehumidifier, we have observed a marked improvement in the quality of our molded parts. The consistently dry plastic materials have eliminated surface defects and significantly enhanced our production efficiency.” – John M., Plastic Molding Company.

“The energy-saving features of the TOPDA hopper dryer have demonstrably reduced our energy expenditure without compromising drying performance. It is a reliable and efficient asset to our plastic extrusion operations.” – Sarah L., Plastic Extrusion Plant.

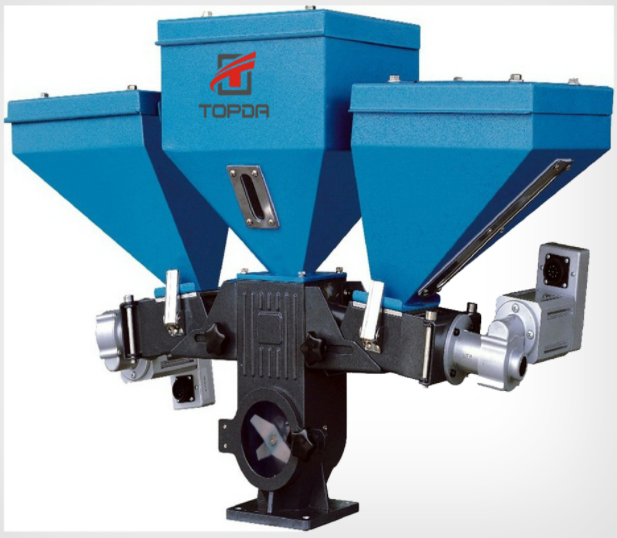

TOPDA PLASTIC HOPPER DRYER MACHINE APPLICATION:

Hot air dryer used in plastic injection machine, extruding machine to dry PP PE PET granules and pellets

Features:

1. Stainless steel structure prevents the material from being polluted;

2. Hopper can be separated from the stand for easy cleaning;

3. High precision temperature controller to control temperature accurately;

4. Overheat protection to ensure machine operation secure and reliable.

Specification:

| Model | Capacity(kg) | Size(mm) | Thickness | Heating (kw) | Blower (kw) | Dimensions(mm) | |

| Path | Height | (MM) | |||||

| RFG-12 | 12 | 255 | 390 | 0.5 | 1.5 | 0.06 | 510*300*660 |

| RFG-25 | 25 | 345 | 425 | 0.6 | 3 | 0.12 | 760*420*851 |

| RFG-50 | 50 | 420 | 550 | 0.6 | 4.5 | 0.18 | 860*500*920 |

| RFG-75 | 75 | 495 | 630 | 0.6 | 6 | 0.3 | 940*540*1140 |

| RFG-100 | 100 | 560 | 630 | 0.8 | 6 | 0.3 | 1050*640*1235 |

| RFG-150 | 150 | 600 | 850 | 0.8 | 9 | 0.4 | 1075*700*1400 |

| RFG-200 | 200 | 700 | 850 | 0.8 | 11 | 0.4 | 1210*750*1500 |

| RFG-300 | 300 | 830 | 1030 | 1.0 | 15 | 0.5 | 1220*800*1630 |

| RFG-400 | 400 | 894 | 1040 | 1.0 | 15 | 0.5 | 1450*940*1800 |

| RFG-600 | 600 | 993 | 1250 | 1.0 | 20 | 1.1 | 1590*1140*2320 |

| RFG-800 | 800 | 800 | 1092 | 1.0 | 30 | 2.2 | 1740*1240*2570 |

| RFG-1000 | 1000 | 1000 | 1092 | 1.0 | 40 | 2.2 | 1740*1240*2820 |

Reviews

There are no reviews yet.