Superior Quality Plastic Hopper Dryer and Dehumidifier Systems

In the plastics processing industry, the importance of properly drying plastic materials cannot be overstated. too much moisture in plastic can lead to a multitude of issues, impacting the quality, strength, and appearance of your molding products. As leading manufacturers specializing in hopper dryer, dehumidifying dryer, and dehumidifier dryer solutions, we at TOPDA provide state-of-the-art plastic dryer and dehumidifier systems designed to ensure your plastic resin is perfectly dry for optimal processing. Our honeycomb dehumidifier technology represents the pinnacle of efficient plastic drying. By choosing TOPDA, you gain access to reliable machinery that enhances your production efficiency and guarantees consistent, high-quality output for your plastic manufacturer needs. Contact us today to learn how our dryer machine solutions can revolutionize your operations.

Eliminate Moisture Issues with High-Performance Dehumidifying Dryers

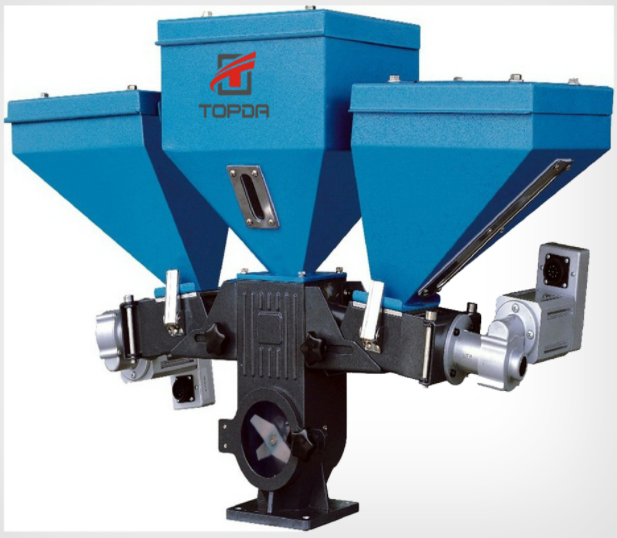

A significant challenge in plastics processing, particularly for plastic film extrudor and plastic bottle manufacturers, is effectively removing moisture in plastic from hygroscopic polymers. Our advanced dehumidifying dryer systems, including the highly efficient honeycomb dehumidifying dryer, are specifically engineered to tackle this problem.

These dryer units employ a sophisticated dehumidification process. Air is first passed through a desiccant rotor, where moisture is adsorbed, achieving an extremely low dew point. This exceptionally dry air is then heated and circulated through the drying hopper containing the plastic granules. The hot air effectively draws out the moisture, which is then carried back to the dehumidifier to be removed by the desiccant. This closed-loop system ensures consistent and thorough plastic drying, preventing common defects like splay, bubbles, and weak weld lines in your injection molding and extrusion processes. Our precise temperature control system safeguards the plastic resin from overheating, maintaining its integrity and ensuring optimal processing. Investing in our dehumidifier dryer technology means investing in the quality and reliability of your finished product.

Optimize Energy Consumption with Innovative Hopper Dryer Designs

In today’s manufacturing environment, energy saving is not just a goal; it’s a necessity. Our hopper dryer units are designed with a strong emphasis on energy-saving features, helping plastic manufacturers reduce their operational costs without compromising on drying efficiency. We understand that for high-volume production, such as that of plastic bottle components, minimizing energy consumption is crucial for profitability.

Our energy saving designs incorporate insulated hoppers to minimize heat loss, optimized hot air distribution systems for uniform drying of plastic granules, and intelligent control system options that allow for precise adjustment of drying parameters based on the specific polymer being processed. Some models also feature a lower return air temperature, which reduces the energy needed for reheating the air. Our integrated hopper dryer and a dehumidifier solutions further enhance efficiency by combining drying and dehumidifying into a single, optimized unit. By choosing our plastic hopper dryer systems, you benefit from superior plastic drying and significant save energy, contributing to a more sustainable and cost-effective operation. Consider pairing this with our High Speed Plastic Mixer PVC Powder Mixing Machine without Cooling Industrial Blender for efficient material preparation.

Enhance Productivity with Integrated Material Handling Solutions

Efficient material handling is integral to a seamless production process in plastics processing. Our offerings extend beyond standalone dryer machine units to include integrated auxiliary equipment for material handling.

We provide various conveying systems designed to smoothly convey plastic granules from storage to the drying hopper and subsequently to the molding machine or extruder. These systems can be tailored to your specific plant layout and production needs, ensuring a continuous and contamination-free flow of raw material. Our Dosing Unit Masterbatch and Regrind Plastic Material Doser Topda allows for accurate blending of materials, further optimizing your process. These automation solutions minimize manual handling, reduce the risk of raw material dust contamination, and contribute to a more productive and efficient plastic molding environment. By integrating our material handling solutions with our high-performance dryers and dehumidifiers, you can create a truly optimized manufacturing setup. Our Sound Proof Bottle Plastic Crusher With Dust Collection can be incorporated for efficient recycling of scrap, further streamlining your operations.

Useful Information:

Technical Specifications (Example):

| Feature | Unit | Value (Example) |

|---|---|---|

| Hopper Capacity | Liters | 100 – 800 |

| Dehumidifying Capacity | kg/hr | 3 – 15 |

| Drying Temperature Range | °C | 60 – 140 |

| Achievable Dew Point | °C | -30 to -50 |

| Power Consumption | kW | 1.5 – 10 |

| Airflow Rate | m³/hr | 80 – 400 |

| Temperature Control | PID |

Usage Instructions (General):

- Ensure the hopper dryer is securely positioned.

- Connect the power supply as per specifications.

- Load the plastic granules into the drying hopper.

- Set the desired drying temperature and time on the control system.

- For dehumidifying dryer models, ensure proper setup for dehumidification.

- Start the drying machine.

- Monitor the drying cycle. Once complete, the dry plastic is ready for processing.

Environmental Impact:

Our focus on energy saving designs in our plastic dryer range helps reduce energy consumption and lower your carbon footprint. Efficient plastic drying also minimizes material waste due to defects.

Customer Reviews (Illustrative):

“The TOPDA hopper dryer has significantly improved the quality of our injection molded parts. We’ve seen a noticeable reduction in moisture-related defects.” – Mark T., Manufacturing Manager.

“We are very pleased with the energy efficiency of the TOPDA dehumidifying dryer. It has helped us lower our operating costs while ensuring our plastic materials are perfectly dry.” – Lisa K., Production Engineer.

Our commitment to providing exceptional plastic drying solutions is driven by our deep understanding of the plastics processing industry. We recognize that different engineering plastics have varying moisture sensitivities and require tailored drying parameters. Our honeycomb dehumidifying dryer units are particularly effective for highly hygroscopic materials, ensuring they reach the optimal dry state without damage caused by excessive heat or insufficient dehumidification. The advanced control system in our drying equipment allows for precise adjustment of the drying temperature and drying time, ensuring optimal results for a wide range of plastic raw materials, including pp and other polymers.

As a leading supplier in the industry, we not only provide high-performance dryers and dehumidifiers but also offer comprehensive support and expertise. Our team can assist you in selecting the ideal plastic dryer solution for your specific application and provide guidance on installation and maintenance. We understand that consistent and reliable plastic drying is particularly important for achieving high-quality molding and extrusion outputs. Our plastic hopper dryer units are designed for durability and continuous operation, ensuring minimal downtime and maximum productivity for your plastic manufacturer plant.

For operations requiring ultra-low moisture content, our honeycomb dehumidifier technology excels. The unique structure of the desiccant rotor provides a large surface area for efficient moisture adsorption, achieving a low dew point that is essential for processing certain engineering plastics used in demanding applications such as the automotive industry. The regenerative nature of the desiccant ensures continuous and reliable dehumidification. Furthermore, features like the return air filter help maintain a clean drying environment, preventing raw material dust from affecting the quality of the finished product.

Reviews

There are no reviews yet.