20+ Years of Industrial Plastic Shredder Manufacturing Expertise – Custom OEM/ODM Solutions Delivered Globally

A trusted manufacturer of eco-friendly resource recycling equipment.

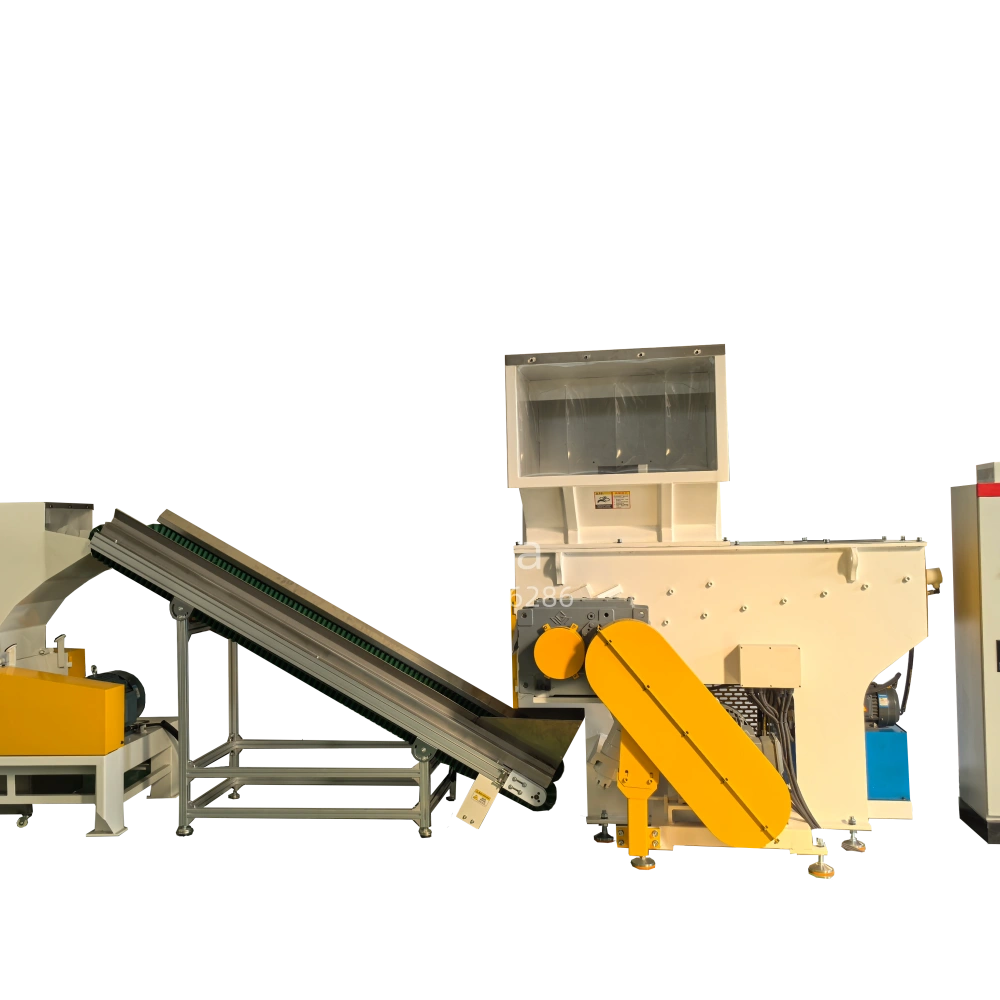

Plastic Shredder effectively processes a wide range of medium to large solid waste, including scrap fabric, waste wood, discarded wires, electronic waste, scrap tires, and aluminum cans, effortlessly managing diverse materials.

Plastic Bottles

Plastic Waste

Waste Pipe

Plastic Barrels

Crushing Process Material

TOPDA Machinery offers customizable shredder to meet specific customer needs, Just provide us with the size and dimensions of the waste you need to process, and we will recommend the ideal plastic shredder for you.

Large PET Bottle Crusher

Pp Pe Pvc Pipe Profile Crusher Machine

Small Plastic Crusher

Soundproof Crusher

Standard Plastic Crusher

Customize

Your

Shredder

REQUEST A QUOTE FOR MORE DETAILS

All You Need To Know About Plastic Shredder

High Crushing Efficiency: TOPDA design provides uniform force distribution for thorough material breakdown, while the adjustable screening mesh boosts processing efficiency.

Reversible Crushing: The unique design enables effective crushing in both forward and reverse rotation, offering exceptional flexibility.

Cost Reduction: An optimized design minimizes maintenance and replacement frequency, lowering overall operational costs.

Increased Reusability: Efficient crushing operations enhance material recycling rates, turning waste into valuable resources.

What Are Plastic Shredder Used For?

Plastic crusher have a wide range of applications in the plastic recycling industry. For example, crushing pipes, films, plastic bottles and other plastic products, etc.

It can also be applied to the following products.

- PE/LDPE/HDPE Film

- PP/BOPP/CPP Fabric And Bags

- PA66 Fishing Net

- PET/BOPET Bottles

- Nylon Products

- PVC Products

- EPS/XPS Foam

- HIPS/PC/ABS Hard Plastic

- PVB Products

- PU Products

TOPDA Plastic Shredder Performance Features

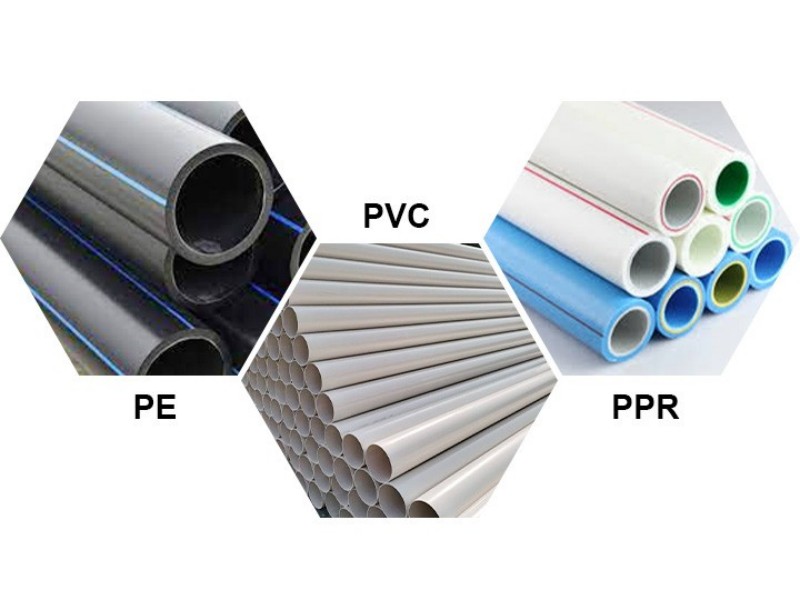

The plastic shredder machine is equipped with a hydraulically driven pusher that automatically feeds material into the processing tool through load-dependent controls. This advanced hydraulic system includes a relief valve and adjustable volumetric flow control, allowing for precise customization to meet specific operational requirements.

Blades

In addition to the common claw knife, flat knife, V shape knife, flower shear knife, we also have more than 20 different knife designs to meet the requirements of customers for different plastic waste crushing.

Crushing Room

The reasonable combination of rotating blade, fixed blade and mesh screen in the crushing chamber can effectively improve the crushing efficiency, optimize the uniformity of crushed particle size and reduce the dust content.

Excellent Powertrain

The drive motor and gearbox are made of excellent Chinese brands, with reliable performance, low failure rate and simple maintenance, which can provide long-term stable operation.

Craft Details

How Do Plastic shredder Work?

The plastic shredder is a device used to crush plastic products into small particles or powder, typically used for recycling old plastic to be processed into new plastic products. It can handle various types of plastics, including polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS), etc. The plastic shredder plays a crucial role in the plastic recycling industry, helping to reduce the environmental impact of plastic waste and promote sustainable development.

Working Principle and Process of Plastic Shredder

How Our Plastic Shredder Works: Efficient Material Reduction

Our plastic shredder uses mechanical force to efficiently break down plastic products into smaller, manageable pieces through a straightforward process:

Feeding: Plastic items, such as discarded products or manufacturing scraps, are fed into the shredder’s intake.

Cutting and Crushing: Inside, powerful rotating blades and rotors cut and crush the plastic into smaller fragments.

Refining: These fragments are further reduced in size through friction and pressure until the desired particle size and shape are achieved.

Screening (Optional): Some models include screens to filter out any unwanted materials, resulting in cleaner shredded plastic.

Output: The final result is small plastic particles or powder, ready for storage, transportation, or the next stage in plastic recycling.

This process makes it easy to handle plastic waste and prepare it for reuse.

Types By Blade

Craw Blade

The claw blade is the most common type of blade for plastic crusher, with a raised surface like a claw, usually with two or more axes of claw cutters to complete the crushing of materials, commonly used to crush hard materials, such as hard plastics, thick materials, etc.

Slice Blade

Slice blades are usually used in crusher machine that crush PET plastic bottles. With the fixed blade and screen in the shredding chamber, the PET bottle flakes can be efficiently and quickly processed into small size flakes.

Flap Blade

The flat blade is suitable for shredding thin and soft materials such as tubes and molded parts. If you have a large variety of plastic waste to crush, then a flat blade is undoubtedly your best choice.

Request A Free Quote

We'd Like To Work With You

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right machine you want.