Plastic Crusher Machines

Plastic crusher often referred to as Plastic Granulator Machine.

Plastic Bottles &Toys

Plastic Crates or Trays

Waste Pipe

PVC Shed

Plastic Barrels

Crushing Process Material

Topda provides plastic recycling machine which can be customized according to customer requirements, such as:bottle crusher, barrel crusher, film crusher,silent crusher, pipe crusher, etc.Crushing plastic waste into smaller pieces for easy recycling since 2008.

Plastic Bottle Crusher

3-150HP

This Plastic Bottle Crusher enables centralized pulverization of various plastics.

Heavy Duty Powerful Plastic Crusher

Designs for injection molding, blow molding, and extrusion forming waste.

Strong Soundproof Plastic Crusher

The feeding Hopper and inner layer are designed with a double-layer soundproof structure on all four sides.

Film Plastic Crusher

Customized size and it can add Metal Separator system

Large crates plastic crusher

30-100HP

Large plate plastic crusher enables centralized pulverization of various plastics.

SS201 PLASTIC CRUSHER

Designs for food

Strong Plastic Crusher Soundproof Type

The feeding Hopper and inner layer are designed with a double-layer soundproof structure on all four sides.

Film Plastic Crusher

Customized size and it can add Metal Separator system

Medium-Speed Crusher

To injection molding machine besides

PLASTIC CRUSHER SS 304

Customize

Your

Crusher

More Options

REQUEST A QUOTE FOR MORE DETAILS

All You Need To Know About Plastic Crusher

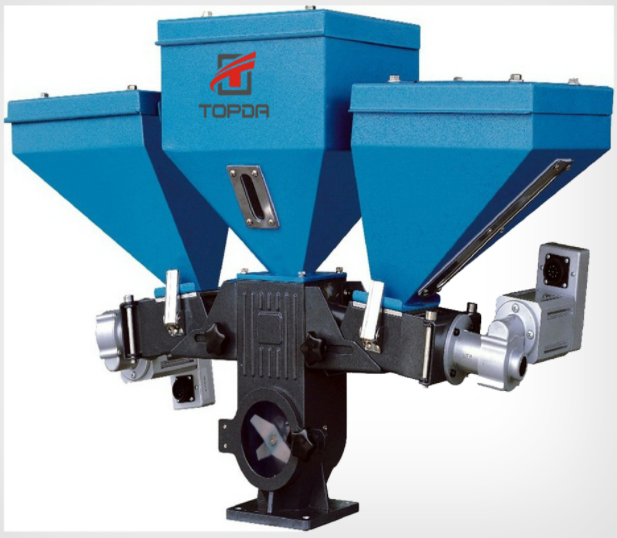

Plastic crushers are specialized recycling machinery integral to the plastic recycling industry. Designed for effective shredding and crushing, these machines utilize a synchronized system of moving and fixed blades, along with a screen, within the crushing chamber to rapidly and safely reduce diverse rigid plastic products into uniform flakes.

As a leading Chinese manufacturer, we possess extensive expertise in producing robust plastic crushers optimized for various recycling lines, including PET recycling lines, plastic film recycling lines, and nylon rope & container bag recycling lines. Our crushers are engineered for durability and consistent performance, contributing to efficient and high-quality recycling processes.

Why Invest in a Plastic Crusher? Enhancing Efficiency and Sustainability

Plastic crushers are essential for reducing the size of plastic waste, making storage and transport more efficient. They are also crucial for plastic recycling, turning scrap into usable regrind for new products. Using a plastic crusher saves space, cuts costs, and supports a sustainable approach to plastics processing.

It can also be applied to the following products.

PE/LDPE/HDPE Film

PP/BOPP/CPP Fabric and Bags

PA66 Fishing Nets

PET/BOPET Bottles

Polyamide (Nylon) Products

Rubber Sprues and Parts

- EPS/XPS Foam

- HIPS/PC/ABS Hard Plastic

- PVB Products

- PU Products

ABS Components

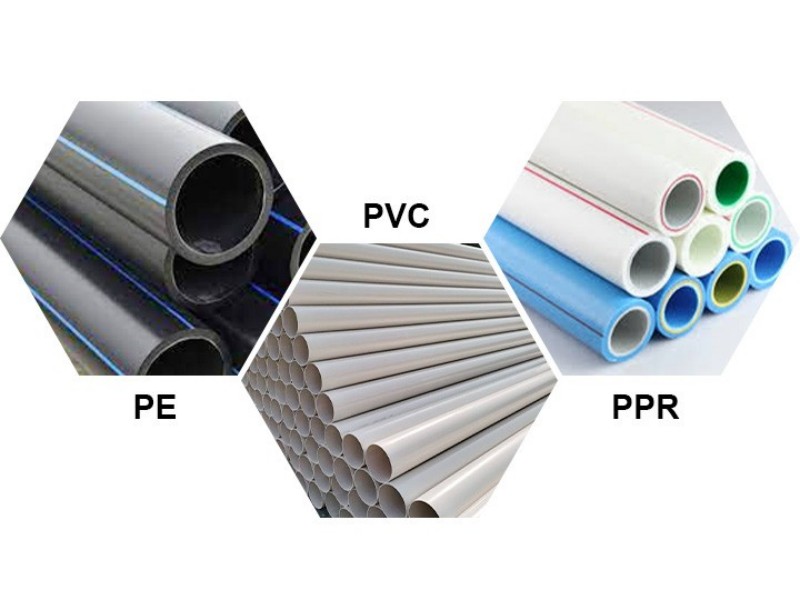

PVC Pipes and Profiles

PC Water Bottles

EPS/EPE Packaging

TOPDA Plastic Crusher Performance Features

Robust Body

Imagine a super strong box that chews up old plastic! That’s kind of like our plastic crusher.It has a robust body structure, which means it’s built to be really tough and last a long time.

This tough body is stainless steel plates. These plates are put together using a special kind of strong glue called seamless welding. This makes the whole thing extra strong and also helps keep the noise down when it’s working.

Crusher Support can be customised by conveyor setting consider. also materials can be 201 stainless steel or 304 stainless steel.

Blades

In addition to the common claw knife, flat knife, V shape knife, flower shear knife, we also have more than 20 different knife designs to meet the requirements of customers for different plastic waste crushing.

Crushing Room

The reasonable combination of rotating blade, fixed blade and mesh screen in the crushing chamber can effectively improve the crushing efficiency, optimize the uniformity of crushed particle size and reduce the dust content.

Double layers Feeding Hopper

SS201 insider ,Steel outside to be more quite .

The reasonable combination of rotating blade, fixed blade and mesh screen in the crushing chamber can effectively improve the crushing efficiency, optimize the uniformity of crushed particle size and reduce the dust content.

Soundproof Designs With Silo Collection

Silent Low noise Design

The feeding hopper is designed with a double-layer soundproof structure on all four sides.The inner layer is constructed made by stainless steel material, while the space between the two layers is filled with sound-absorbing materials.This design effectively reduces noise transmission and provides excellent sound insulation properties, resulting in a quieter operating environment.

Plastic Crusher Main Parts

How Do Plastic Crusher Work?

When the motor is connected to the dynamic blade rotation, and the cutting chamber of the fixed blade to form a relative movement, when the material into the cutting chamber, by gravity, the material through the gap between the rotating dynamic blade, the fixed blade and mesh screen can complete the material cutting and grinding.

WHY Topda Is Your Reliable Plastic Crusher Manufacturer and Supplier In China?

- Designs and Machines are Flexible

Depending on the properties of the crushed material, the crusher can be equipped with different rotors, blade structures

- Automatic Open and Easier Cleaning

You only need to open the cover, you can do simple cleaning. Of course, in the process of cleaning, be sure to turn off the power to ensure safety.

- Low Noise and Dusty

Can be retrofitted with sound insulation to reduce working decibels to 80 db and lower .

Dust will be separated from outlet and collected by Silo .

- Easy maintenance

The crusher’s modular design allows for swift disassembly and thorough cleaning of key components. Telescoping and adjustable tool mounts enable precise resharpening, maximizing cutter longevity.

Making the Right Choice: What to Consider When Purchasing a Plastic Crusher

#1 What Plastic Material And How Large it is ?

When selecting a plastic crusher, consider your primary material processing needs. For PVC pipes, plastic bottles, tubes, material drums, or rigid plastic shells, TOPDA’s experts can recommend optimal crusher models based on your desired output size and processing capacity.

#2 Crushing Efficiency/Effectiveness

Crusher efficiency is influenced by motor power, the number of plastic crusher shafts, and plastic crusher design. Increased plastic crusher shafts generally enhance crushing efficiency and output quality. Blade selection directly determines the size and shape of the processed material. Collaborating with our specialists ensures the crusher is configured to meet your specific operational requirements.

#3 Crusher Motor Power

Crusher power directly correlates with processing capacity. Options range from 5 HP, yielding approximately 100 kg/h , to 100 HP, achieving around 2 tons/h, allowing for capacity matching to overall production line efficiency.

#4 Plastic Grinder Body Materials

The crusher can be manufactured from various materials, including A3 steel, 201 stainless steel, and 304 stainless steel, to suit specific application needs. Noise reduction to 85 decibels is achievable through the incorporation of sound-dampening materials.

#5 Soundproof And Dust Remover System For Optional

For a soundproof plastic recycling solution, ensure the crusher incorporates:

A fully enclosed crushing chamber with comprehensive sound insulation foam lining. This minimizes noise emission during operation.

A sealed body structure design. This further contains noise and prevents dust leakage.

Additionally, consider integrating a dust removal system, enabling direct transfer of processed material to the next stage.

Types By Blade

Craw Blade CI9SI materials :

Specially Designs For Hard Plastic Materials

Claw blades, characterized by their raised, claw-like cutting surfaces, are a prevalent blade type in plastic crushers. Typically employed in multi-rotor configurations, they excel at the efficient size reduction of rigid and high-density plastics, including hard plastics and thick-walled materials.

Flake Blade Crushers for Efficient PET Bottle Flake Processing

The flake-type plastic crusher is capable of shredding various plastic products, including common sheets, pipesprofiles, plates, and packaging materials. lt can also handle sprue materials such as runners, edge trim, circuitboards, automotive parts, bumpers, computer keyboards, air conditioner casings, aluminum composite panel scable sheaths, LED strips, and more. The versatility of the blade-type plastic crusher makes it suitable for a wide range of plastic materials and applications.

Plastic crusher with Silo Collection Dust remover

Flat blades are optimally suited for shredding flexible and low-density plastics, such as tubes and molded parts. For operations handling a diverse range of plastic waste streams, flat blade crushers offer exceptional versatility and efficient material reduction.

Request A Free Quote

We'd Like To Work With You

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right machine you want.

- 008618822886286

- [email protected]

- 0086 188 2288 6286