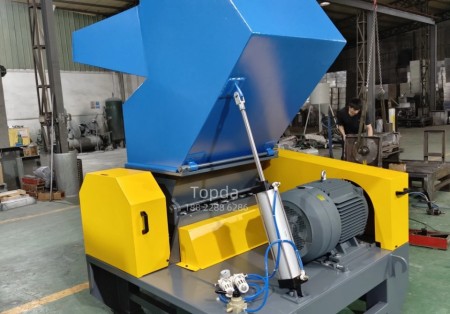

Plastic Crusher Machine for Grinding Long Plastic Pipes

Crusher - Plastic Crusher Machine For Grinding Water Bottle Waste

The Plastic Crusher Machine for Long Plastic Pipes is specifically designed to process extended plastic pipes and profiles. Its reinforced welded steel cavity forms a fixed angle with the horizontal feeding hopper, which remains nearly parallel to the ground for effortless loading of heavy materials like small-diameter PVC pipes and profiles.

The Pipe Shredder crushes long plastic profiles, pipes, rubber hoses, door frames, and sheets. Its angled feed inlet simplifies loading, reducing labor for bulky materials. Add a suction fan and storage bin (optional) to create a seamless recycling system. Perfect for recycling plastic, metal, and rubber pipes.

A unique safety mechanism prevents overload—if excessive solid waste enters the crushing chamber, the rotor automatically stops intake until existing material is processed, eliminating blockages. Available with rotors measuring 560mm, 600mm, or 700mm in diameter and lengths up to 1400mm, the machine features a V-shaped rotor design to boost cutting efficiency while reducing dust in processed flakes. Built-in antiwear plates and external bearings safeguard the crushing chamber from contamination.

Ideal for small-diameter pipes (16-450mm PE, PP, or PVC) and wide panels/sheets, this plastic pipe crusher supports optional accessories like feeding conveyors, suction fans, and storage systems to maximize productivity.

Specialized Alloy Blades

Equipped with high-strength alloy blades 9crsi / SKD-ii and an optimized chamber design, it rapidly reduces pipes to uniform granules, maximizing throughput.

Automatically Open Chamber Room

Equipped with high-strength alloy blades 9crsi / SKD-ii and an optimized chamber design, it rapidly reduces pipes to uniform granules, maximizing throughput.

Crusher Motor

CRUSHING CHAMBER

The crushing chamber is fabricated from 40mm ultra-high hardness steel plate This material delivers wear resistance and corrosion resistance , enabled by advanced microstructural engineering and nanoparticle co-precipitation techniques . Its low-noise operation and extended service life stem from ultra-high hardness and resistance to abrasive wear. The welded construction ensures structural integrity , while optimized alloy composition avoids limitations of low-carbon steels

The welded structure incorporates a frame positioned on shock-resistantrubber-metal connectors, effectively resisting shocks and reducing noise

Plastic Crusher Frame Blade Support

Utilizing famous brand motors, ensuring low energy consumption, minima noise, and an extended service life.

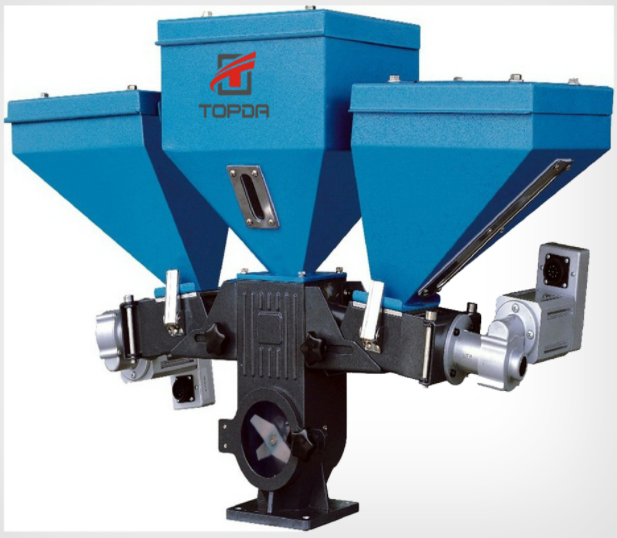

Plastic Grinder - Plastic Crusher Machine For Water Bottle Waste

Plastic Grinder - Dust Remover & Silo

The Crusher – Plastic Crusher Machine For Grinding Long Plastic Pipes are engineered to grind lengthy plastic pipes and profiles. A robust steel cavity, welded together, creates a fixed angle with the horizontal feeding hopper.

| Item | Unit | TT-GP600/500 | TT-GP560/700 | TT-GP560/1000 | TT-GP700/1400 |

| Feed opening | mm | 440*440 | 640*280 | 910*280 | 1440*320 |

| Rotor diameter | mm | 600 | 560 | 560 | 700 |

| Rotor speed | rpm | 560 | 470 | 470 | 410 |

| Motor power | kw | 37 | 55 | 75 | 110 |

| Number of rotor knives | pcs | 5*2 | 5*2 | 5*2 | 5*3 |

| Number of stator knives | pcs | 2 | 2 | 2 | 2 |

| Hydraulic power | kw | 1.5 | 1.5 | 1.5 | 1.5 |

| Standard screen | mm | 6~30 | 6~30 | 6~30 | 8~30 |

| Chamber size | mm | 516*498 | 716*650 | 985*650 | 1400*700 |

| Machine Length | Inches | 88.58 | 94.49 | 94.49 | 97.64 |

| Machine Length | Inches | 73.23 | 86.61 | 86.61 | 91.34 |

| Machine Width | Inches | 53.15 | 70.87 | 80.71 | 94.49 |

| Machine Width | Inches | 32.28 | 41.73 | 58.27 | 72.44 |

| Machine Height | Inches | 63.78 | 68.9 | 68.9 | 77.95 |

Get An Instant Quotation Now

How Can We Help You?

Contact our sales team for a quotation.