Selecting the best plastic crusher blades

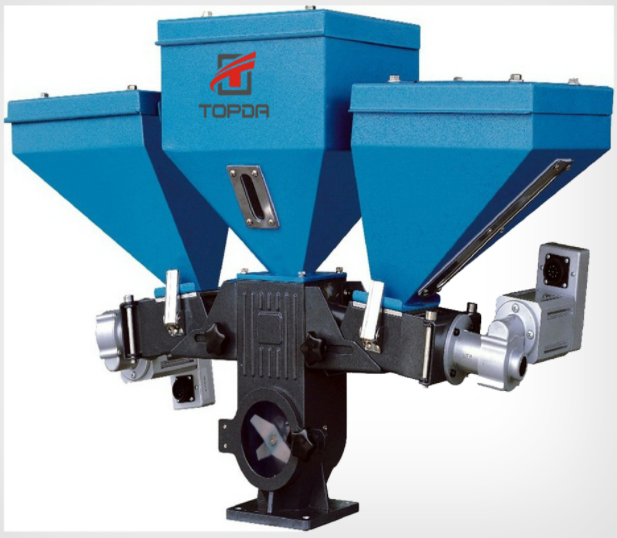

Selecting the best plastic crusher blades is critical for efficiency, durability, and cost-effectiveness in plastic recycling. At TOPDA, we recommend evaluating these key factors to optimize your crushing performance:

1. Blade Material Matters

- Hard Plastics (e.g., Polypropylene, ABS): Use carbide blades for superior hardness and wear resistance.

- Soft Plastics (e.g., Polyethylene, PVC): Tungsten carbide blades offer better toughness and impact resistance, reducing premature wear.

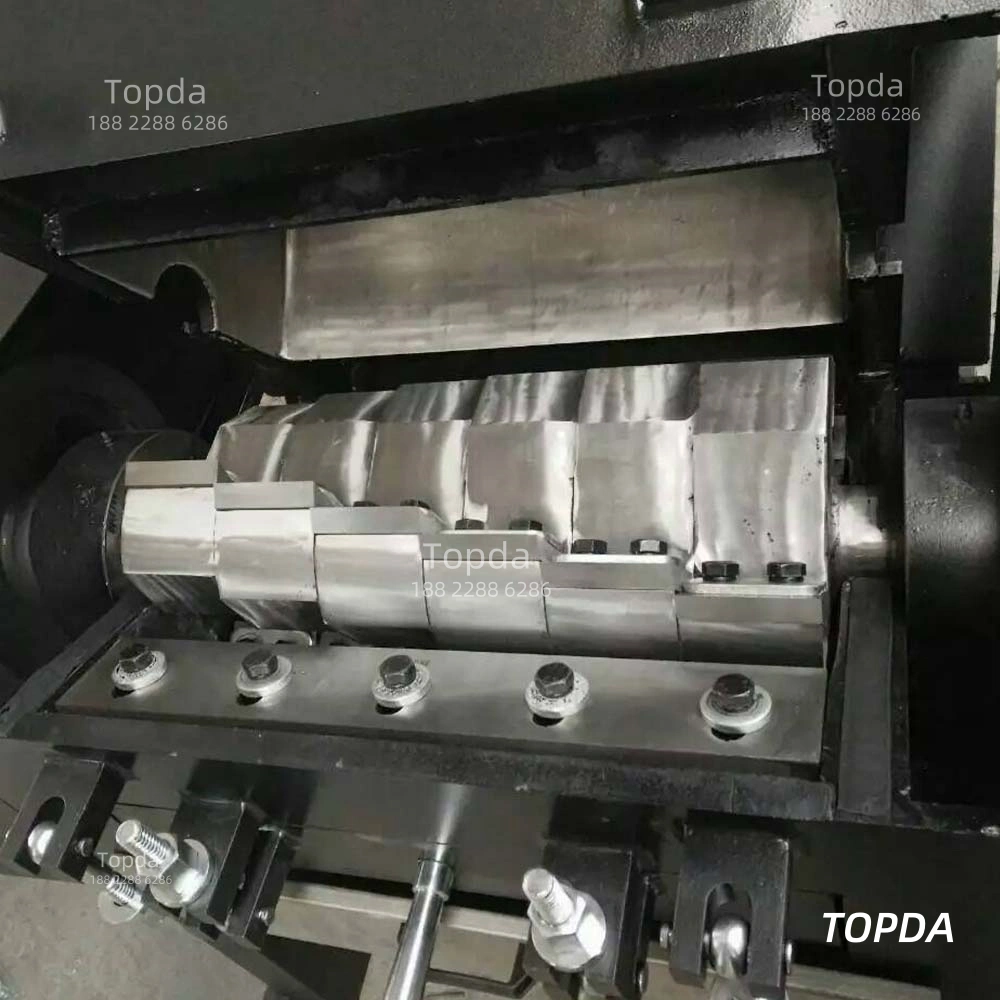

2. Blade Structure for Different Applications

- Solid/One-Piece Blades: Ideal for large plastic parts—high rigidity ensures stable, uniform crushing.

- Inserted/Modular Blades: Perfect for small or irregularly shaped plastics, allowing customization for diverse shapes.

- Claw Blades (Claw Type): Excellent for film, fibers, and tough materials, providing aggressive shredding.

3. Sharpness = Efficiency

A sharper blade reduces energy consumption and processing time. TOPDA’s precision-ground blades ensure:

- Faster crushing cycles

- Lower operational costs

- Consistent output quality

4. Longevity Saves Costs

Invest in long-life blades to minimize downtime and replacement expenses. Our blades feature:

- High-grade materials

- Advanced heat treatment

- Corrosion-resistant coatings

Why Trust TOPDA’s Plastic Crusher Blades?

- Custom Solutions: Tailored for your plastic type and production needs.

- Proven Durability: Engineered for extended service life.

- Global Standards: Precision manufacturing for maximum efficiency.

Need Expert Advice?

Contact TOPDA today to find the perfect crusher blades for your plastic recycling machine!