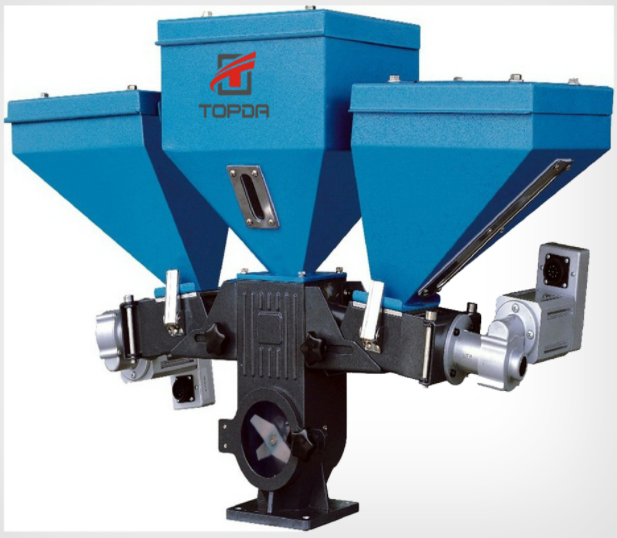

Horizontal Mixer

Often referred to as Ribbon Mixer or Batch Mixer

Horizontal mixers combine two or more ingredients together in a mixing chamber. The mixer uses ribbon blades or screw paddles to move the substances around and combine them. This provides for a smooth, consistent combination that is ideal for your business requirements.

Customize Your Horizontal Mixers

The volume of the mixing chamber, the mixing blades and other accessories can be customised to suit the mixing of solid mixtures, powders, granules and other raw materials.

REQUEST A QUOTE FOR MORE DETAILS

All You Need To Know About Horizontal Mixer

Horizontal mixers are a common industrial type equipment for the efficient and rapid mixing of bulk, heavy, granular, high viscosity or non-flowing raw materials.

The whole machine, the center shaft and “S” type ribbon are made of stainless steel, strong and durable, good homogenization effect.

Manual or pneumatic discharge port can also be made according to

customer requirements.In addition, we can also add heating and drying function to the mixer.

What Are Horizontal Mixer Used For?

Horizontal mixers are used for a variety of purposes in a business setting. Some of the most common applications include:

- Powder mixer

- Plastic building materials

- Plastic granulation

- Color masterbatch making

- Gentle product homogenization

- Recycling of recycled materials

- Emulsifying products

- Pasty mixtures

- Feed

- Easy To Fix

Due to its simple design, it is easier to replace and repair parts than other mixer types. Check out all the top Chinese horizontal mixer manufacturers in this article based on the above factors and select the right one for your application.

- Cost-effective

Horizontal mixer do not cost much and last a long time. The minimalist structure is an important factor in the very low failure rate of horizontal mixer.

Considerations When Buying Horizontal Mixer

#1 What Materials To Mix

Different people have their own ideas about what material to mix in a horizontal mixer.

Are they granular? Powdery? Sticky? Flaky? Easily corrosive? All of these questions should be in your mind, and NICETY MACHINERY’ S sales staff will provide you with the best configuration for your line, including the raw material for the barrel and the blade style (scroll down to see the blade style and suitable application scenarios).

#2 Power

You need to decide how much power you need the mixer to have. If you will only be using it for small tasks, a low-powered mixer should suffice. However, if you plan on using the mixer for more heavy-duty tasks, then you will need a model with more power.

#3 Heating And Drying Function

This is an option for customers who need the material to remain dry during the mixing process. Nathan Machinery’s horizontal mixers can be customized with heating and drying functions, and the reasonable barrel shape structure can reduce heat loss and improve drying efficiency. If you are interested, please feel free to ask the staff of NICETY Machinery to provide you with customized service!

#4 Body Materials

Can be made of different materials according to your requirements, such as: A3 steel, 201 stainless steel, 304 stainless steel, etc.

#5 The Entire Production Line System

The horizontal mixer is only one part of the equation. Considerations should include the requirements of the entire system. For example, location of discharge port, the purpose of the production system is related to the suitability of the material.

Helical Ribbon Blade

It is the most common blade style, the inclined blades extending to the vessel wall move the material in one direction, while the inner inclined blades move the material in the opposite direction, it has a larger contact area than the pulp or plough type mixer and is more widely applicable, more suitable for free flowing, crumbly, granular, low viscous materials. Usually the mixing can be completed in 5-10 minutes.

304 Stainless Steel

304 stainless steel is a common type of stainless steel in life, the household appliances you use and even the faucets may be made of 304 stainless steel. It has better corrosion resistance than 201 stainless steel

More Options

Depending on your use scenario, there are many options for steel. If your product is a very corrosive chemical, the more expensive 316 stainless steel is obviously more suitable, and although expensive, it is worth it.

Request A Free Quote

We'd Like To Work With You

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right machine you want.