Crushed plastic pellets (regrind) are versatile engineered materials driving circular economies. Their standardized size and composition enable high-value recycling across industries, reducing virgin plastic demand by up to 30-50% in manufacturing. Here’s how they transform waste into resources:

1. Manufacturing Regenerated Products

Crushed pellets serve as primary feedstock for injection molding and extrusion. Reprocessed via industrial equipment like TOPDA’s High-Speed Plastic Mixer, they yield homogeneous blends for:

- Containers & Packaging: Food-grade rPET pellets (meeting FDA 21 CFR/EC 10/2011 compliance).

- Automotive Parts: PP/ABS pellets with >95% purity (tested per ISO 11469).

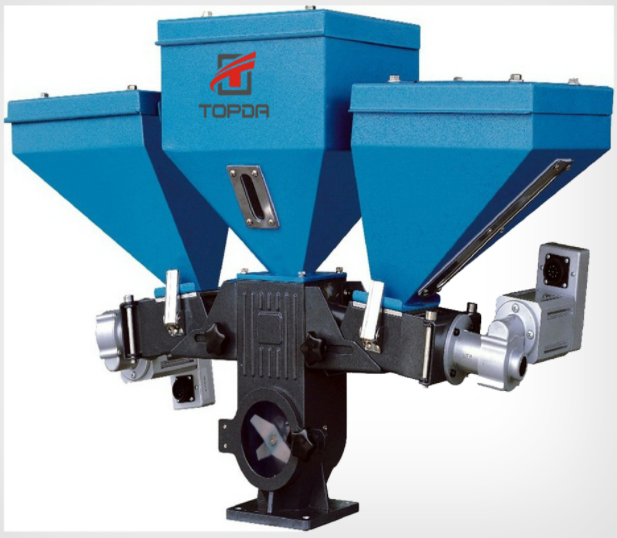

- Consumer Goods: Uniform pellets for toys, furniture, and bins (color consistency ΔE<1.0 via TOPDA’s Volumetric Dosing Unit).

2. Performance-Enhanced Composites

As functional fillers (15-40% loadings), pellets boost material properties:

- Rubber/Concrete: Improve tensile strength (ASTM D638) and reduce density.

- Insulation Materials: Achieve thermal resistance R-values ≥ 4/in (ASTM C518).

TOPDA’s Dosing Units ensure precise regrind/masterbatch ratios for optimal compounding.

3. Construction & Infrastructure

- Lightweight Concrete Aggregates: Pellets reduce weight by 25% vs. traditional fillers (EN 13055-1 certified).

- Waterproof Membranes: HDPE/LLDPE pellets enhance flexibility (-40°C to 80°C operational range).

- Composite Decking: UV-stabilized pellets (tested per ASTM D4329) resist fading.

4. Agricultural Efficiency

- Irrigation Systems: Pellets extrude into drip tapes (withstand 60 PSI pressure, ISO 9261).

- Mulch Films: LDPE pellets enhance biodegradability (OK Biodegradable Soil certification).

5. Advanced Material Innovation

- 3D Printing Filaments: Size-controlled pellets (≤3mm) ensure flow consistency (MFR 5-30g/10min, ISO 1133).

- Biomedical Scaffolds: Medical-grade PP pellets (ISO 10993 biocompatibility).

Why Particle Quality Matters

Inconsistent pellet size (>±5mm) or contamination (>0.5%) compromises end-product integrity. TOPDA’s shredding technology guarantees precision:

TOPDA V-Series Heavy-Duty Shredders:

- Dual Knife Systems:

- Flat Blades: For rigid plastics (e.g., PVC pipes).

- Claw Blades: For films/fibers.

- Tool Steel Cutters: D2/D6 high-chromium alloy (HRC 58-62), tested for 1,000+ operating hours.

- Optimized Geometry: 25° increased cutting angle improves efficiency by 30% (output: 100-5,000 kg/h).

- Dust & Noise Control: Integrated systems (≤75 dB(A), EN ISO 3744) like the Soundproof Granulator.

Validated by:

- Size Uniformity: SPI PP-001 standards (95% within ±2mm tolerance).

- Purity Screening: Metal detection (ferrous/non-ferrous) and air classification.

TOPDA: Engineering Recycling Excellence

With 10+ years in plastic recycling, TOPDA delivers CE/ISO-certified solutions:

- Pre-Shredding: Single Shaft Shredders for bulky waste.

- Size Reduction: Plastic Crushers producing 3-15mm pellets.

- Material Handling: Automated dosing/blending systems.

“TOPDA shredders achieve 99% granulation yield – maximizing pellet usability while minimizing waste.”

Drive Sustainability with Precision-Ground Pellets

From construction to biotech, TOPDA’s shredding systems unlock plastic’s circular potential. Explore our Plastic Recycling Machines for ASTM/ISO-compliant pellet production.