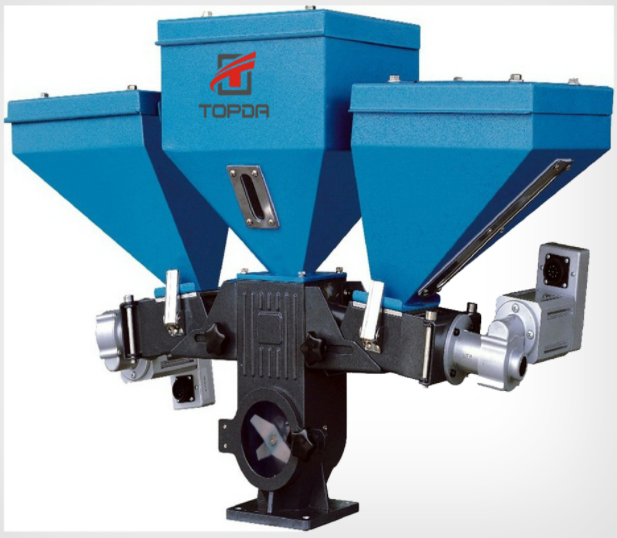

Plastic crushers are essential equipment in the plastic recycling and reprocessing industry. Assessing the crushing capacity of a plastic crusher is crucial for determining its performance and selecting the right machine for your needs. At TOPDA, we adhere to strict industry standards and testing protocols to ensure our plastic crushers deliver optimal performance. Below are the key factors and testing methods used to evaluate plastic crusher efficiency.

1. Crushing Efficiency: Throughput Rate & Power Consumption

Crushing efficiency is measured by the throughput rate (kg/h) and specific energy consumption (kWh/kg). High-performance crushers, like TOPDA’s industrial-grade models, process large volumes of plastic with minimal energy waste.

- Testing Standard: ASTM D6869 (Standard Test Methods for Testing Plastic Materials)

- Measurement:

- Throughput Rate = Total plastic processed (kg) / Processing time (h)

- Specific Energy Consumption = Power input (kWh) / Plastic processed (kg)

2. Crushing Granule Size: Particle Distribution Analysis

The particle size distribution (PSD) determines the uniformity of crushed plastic granules. A narrower PSD range indicates better consistency.

- Testing Standard: ISO 3310-1 (Test Sieves)

- Measurement:

- Sieve analysis using mesh sizes (e.g., 5mm, 10mm, 20mm)

- D50 Value (Median particle size) for quality control

3. Noise & Vibration Levels: Workplace Safety Compliance

Excessive noise and vibration can impact operator safety and machine longevity. TOPDA’s low-noise plastic crushers comply with international workplace safety regulations.

- Testing Standard: ISO 4871 (Noise Emission) & ISO 10816 (Vibration)

- Acceptable Limits:

- Noise: < 75 dB(A) at 1m distance

- Vibration: < 2.5 mm/s RMS

4. Durability & Wear Resistance: Material & Structural Testing

A high-quality plastic crusher should withstand prolonged operation with minimal wear.

- Testing Methods:

- Hardness Test (Rockwell Scale) for blade durability

- Fatigue Testing (10,000+ cycles) for structural integrity

- Corrosion Resistance Check (ASTM B117 Salt Spray Test)

5. After-Sales Support & Maintenance Services

TOPDA provides 24/7 technical support, spare parts availability, and preventive maintenance programs to ensure long-term reliability.

Conclusion: Choosing the Right Plastic Crusher

When selecting a plastic crusher, consider:

✅ High throughput rate & low energy consumption

✅ Consistent granule size (D50 value)

✅ Low noise & vibration for safe operation

✅ Robust construction & wear-resistant materials

✅ Reliable after-sales service & maintenance

For industry-leading plastic crushers with certified performance, explore TOPDA’s range of heavy-duty and silent plastic crushers today!