Introduction: Beyond Weight Savings – The Multifaceted Advantages of Aerospace Plastics

Advanced polymers are indispensable in aerospace engineering, far surpassing their fundamental benefit of weight reduction. Their unique combination of exceptional heat resistance, superior chemical stability, and outstanding mechanical properties makes them mission-critical for spacecraft and satellite design. These materials must reliably perform under extreme space conditions: intense thermal cycling, corrosive environments, and high radiation levels. The versatility of engineering plastics enables creation of complex, high-performance components essential for spacecraft integrity and function.

Key Applications: Where Plastics Excel in Aerospace

- Structural & Exterior Components: Advanced thermoplastics and composites create lightweight yet robust airframes, fairings, and housings. Their thermal stability protects against severe temperature fluctuations during launch, orbit, and re-entry.

- Electrical & Electronic Systems: Plastics provide critical electrical insulation in wiring, connectors, and avionics enclosures. Materials like PEEK and specialized polyimides offer excellent dielectric properties, shielding sensitive electronics from interference.

- Interior Systems & Functional Parts: From cabin components to specialized seals, plastics deliver durability and chemical resistance while enabling intricate geometries that optimize confined spacecraft interiors.

Material Performance: The Non-Negotiable Aerospace Standard

Every component must meet rigorous specifications where failure is catastrophic. Aerospace-grade plastics are selected for their proven ability to:

- Maintain integrity under extreme stress (-270°C to +300°C+)

- Resist degradation from fuels, oxidizers, and cosmic radiation

- Enable precision manufacturing of complex geometries

- Deliver consistent performance batch after batch

TOPDA: Enabling Aerospace-Grade Material Preparation

For over 30 years, TOPDA has pioneered precision plastic processing solutions that meet aerospace manufacturing demands. Our technologies ensure optimal material preparation – the critical first step in producing high-performance components:

1. Precision Size Reduction for Recycled Aerospace Polymers

TOPDA’s heavy-duty shredders and granulators, like our V-Series Plastic Shredders, transform post-industrial aerospace plastics into consistent, high-purity regrind:

- Dual-Blade Innovation: Optional flat blades or claw blades optimize processing for different aerospace polymers (e.g., reinforced PEEK, PPS, PEI)

- Precision Cutting Geometry: Strategically positioned pre-cutters increase effective cutting angles, boosting throughput while maintaining exceptional granule uniformity

- Critical Consistency: Uniform particle size ensures predictable flow characteristics and material behavior in molding/extrusion – essential for mission-critical components

- Advanced Filtration: Integrated dust collection systems (as featured in our Sound Proof Granulators) maintain material purity and workshop cleanliness

Explore TOPDA’s Plastic Shredding Solutions:

2. Precise Material Formulation & Blending

Creating specialized aerospace composites requires absolute precision:

- High-Speed Mixing Technology: Our industrial blenders achieve homogeneous distribution of additives, reinforcements, and colorants in engineering plastics

- Thermal Control: Advanced mixing systems ensure uniform thermal profiles without material degradation

- Batch Consistency: Critical for maintaining certified material properties in flight components

Discover TOPDA’s Mixing Systems:

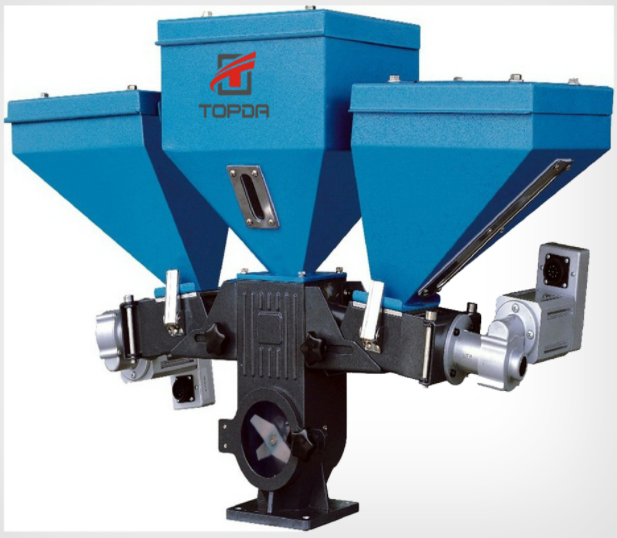

3. Precision Metering for Composite Manufacturing

TOPDA’s dosing systems ensure exact material ratios for high-performance composites:

- Volumetric Accuracy: Critical when incorporating regrind, masterbatches, or specialized additives

- Contamination-Free Operation: Ensures material purity for sensitive aerospace applications

- Seamless Integration: Works with injection molding and extrusion lines

TOPDA Dosing Solutions for Aerospace:

Sustainable Aerospace: Closing the Loop with TOPDA

The industry’s sustainability focus makes efficient recycling paramount:

- Closed-Loop Systems: Our shredding and granulation technologies enable high-value recycling of aerospace polymers

- Resource Efficiency: Converting production scrap into certified regrind reduces virgin material consumption by up to 30%

- Space Debris Mitigation: Terrestrial recycling directly reduces potential orbital waste sources

- Cost Optimization: Quality regrind incorporation lowers manufacturing costs without compromising performance

Partner with TOPDA for Aerospace Manufacturing Excellence

From material recycling to precision formulation, TOPDA’s 30+ years of engineering expertise supports the entire aerospace plastic value chain:

- Certified Regrind Production: Consistent, contaminant-free granules from our shredders

- Precision Blending: Homogeneous material preparation for composites

- Exact Metering: Repeatable accuracy for critical formulations

Leverage our robust processing solutions to meet AS9100 standards and manufacture higher-performing, more sustainable spacecraft components.

Contact TOPDA today to discuss aerospace-grade plastic processing solutions.