Plastic shredders and granulators efficiently recycle waste into reusable materials. Discover types, shredder vs. granulator functions, and benefits for injection molding/waste management. Optimize recycling processes, reduce environmental impact, and select ideal equipment to transform plastics sustainably. Boost resource efficiency now.

Choosing the Right Industrial Plastic Shredder & Granulator for Maximum Benefits

Article Outline

- What Exactly is a Plastic Shredder and Why is it Crucial for Waste Management?

- How Does a Plastic Shredder Machine Actually Shred Plastic? The Shear Mechanics Explained.

- What are the Different Types of Shredding Machines for Plastic Recycling?

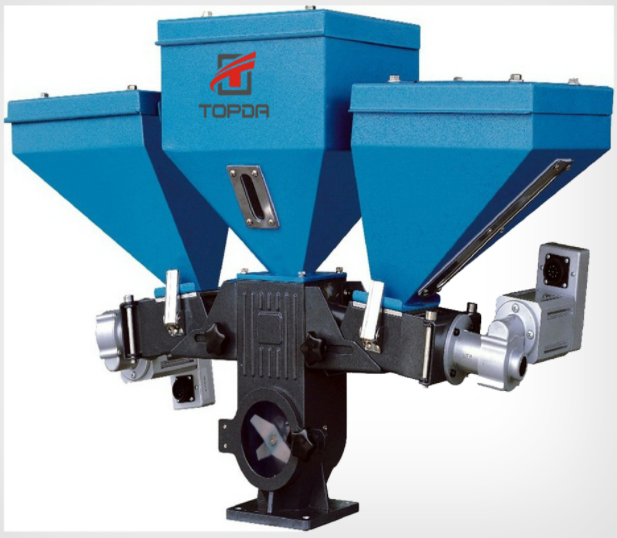

- Industrial Shredder vs. Granulator: What’s the Difference for Solid Waste Processing?

- What are the Key Benefits of Plastic Shredding in the Recycling Process?

- How Can a Plastic Crusher Help Reduce the Size of Materials Effectively?

- What Factors Should You Consider When Choosing the Right Plastic Shredder?

- Are Plastic Granulators More Cost-Effective for Certain Types of Plastic?

- Beyond Recycling: What Other Applications Use Industrial Shredder Technology?

- How Do We Ensure the Chosen Shredder Handles the Right Plastic and Size of Materials?

What Exactly is a Plastic Shredder and Why is it Crucial for Waste Management?

A plastic shredder is a vital machine in recycling systems, efficiently breaking down bulky plastic waste (containers, pipes, scrap) into uniform flakes. This size reduction cuts transport/storage costs and prepares materials for washing, melting, and pelletizing. Essential for circular economies, shredders transform landfill-bound plastics into reusable feedstock for new products. Robust shredders optimize recycling workflows, enabling efficient downstream processing while combating plastic pollution.

How Does a Plastic Shredder Machine Actually Shred Plastic? The Shear Mechanics Explained.

Plastic shredders grind plastic into small pieces using sharp blades that spin and slice like scissors. They have strong steel blades that stay sharp, handling different plastics—hard ones break easily, while soft ones need more force. How the blades are shaped, how fast they spin, and the motor’s power affect how well the machine works. Screens help control the size of the shredded pieces. Heavy-duty shredders use tough coatings to resist wear from rough materials. Unlike crushers that smash plastic, shredders slice it into bits for recycling. Important factors: plastic thickness, blade sharpness, and durability. Simple, efficient, and built to last.

What are the Different Types of Shredding Machines for Plastic Recycling?

Types of Plastic Shredders for Efficient Recycling Operations

Not all plastic recycling machines work the same way. Choosing the right shredder depends on your plastic type, volume, and recycling goals. Here’s a simple breakdown of key options:

- Single-Shaft Shredders

- Versatile: Ideal for films, fibers, and rigid plastics.

- Design: Uses one rotor with blades to cut materials against fixed knives.

- Best For: Mixed or general-purpose plastic recycling.

- Two-Shaft Shredders (Dual-Shaft)

- Powerful: Features two rotating shafts with interlocking blades for aggressive shredding.

- Handles: Bulkier plastics and materials with minor contamination.

- Action: Shear-cutting for consistent results.

- Four-Shaft Shredders

- High Precision: Controls particle size using screens for uniform output.

- Best For: Heavy-duty tasks and demanding recycling applications.

- Specialized Shredders

- Tough Materials: Designed for large, dense plastics (e.g., drums, industrial waste).

- Unique Needs: Customized for specific plastic types or shapes.

Shredder vs. Crusher for Plastic Recycling

While crushers break brittle plastics with impact force, shredders are better for most recycling. Their cutting blades create evenly sized pieces, improving sorting and processing efficiency.

Choosing the Right Machine

- Volume: High-capacity shredders for large-scale operations.

- Plastic Type: Match the shredder to your material (films, rigid plastics, etc.).

- Contamination: Dual-shaft models handle dirtier inputs.

Bonus Use: Some shredders also process paper, textiles, or medical waste, adding flexibility to recycling facilities.

By understanding these options, you can optimize your plastic recycling workflow for better results and cost savings.

What are the Key Benefits of Plastic Shredding in Recycling?

Plastic shredding boosts recycling efficiency through volume reduction, cutting transport/storage costs. Shredded plastic is easier to wash, sort, and process, enhancing material homogeneity. Shredders expand facility capabilities, handling diverse plastics (e.g., hard drive casings) and improving recycled purity. This reduces landfill waste and creates reusable raw materials.

How Can a Plastic Crusher Reduce Material Size Effectively?

Plastic crushers use impact/compressive forces to break down hard, brittle plastics. Unlike shredders (shear-based), crushers suit rigid blocks or purgings. However, shredders are better for ductile plastics (films) due to uniform particle output. Crushers may pre-process materials before shredding, depending on recycling setup goals.

What Factors Matter When Choosing a Plastic Shredder?

Key considerations:

- Material type (PET, HDPE, films) and blade compatibility.

- Throughput and output size (fine vs. coarse).

- Feedstock dimensions (hopper size) and contamination tolerance.

- Maintenance (blade access), energy use, safety features, and space. Test materials with manufacturers to optimize shredder configuration.

Are Plastic Granulators More Cost-Effective for Specific Plastics?

Granulators excel with clean, pre-sized scrap (e.g., production offcuts), creating uniform granules for direct reuse. They save costs by skipping secondary processing but struggle with contamination or bulky items. Shredders remain vital for initial size reduction in mixed waste streams.

Beyond Recycling: What Industries Use Industrial Shredders?

Shredders serve document destruction, e-waste, tire recycling, wood/biomass processing, and medical waste sterilization. They handle diverse materials (metal, polymers) by adjusting blade/rotor designs, proving essential for waste management across sectors.

How to Ensure a Shredder Handles the Right Plastic & Size?

Analyze feedstock (polymer type, dimensions) and conduct material trials with manufacturers. Choose shredders with specialized features:

- Film-focused rotors to prevent wrapping.

- Heavy-duty drives for thick plastics.

- Optimized blade material/design for longevity. Prioritize manufacturer collaboration to match machine specs to your waste stream.