Revolutionizing Plastic Recycling: The Ultimate Guide to Crusher Blade Materials

The Plastic Pvc Waste Problem

Imagine mountains of plastic waste choking our plane. Every year, millions of tons of plastic bottles end up in landfills, creating an environmental nightmare. Manufacturers and recycling centers struggle with inefficient crushing technologies that:

- Waste energy :plastic bottle, plastic film,plastic bag,plastic waste

- Increase operational costs

- Reduce recycling efficiency

The Hidden Challenges

Plastic recycling isn’t just about crushing—it’s about smart engineering. Traditional methods fail because:

- Blades wear out quickly

- Different plastics require unique cutting approaches

- Contamination reduces material quality

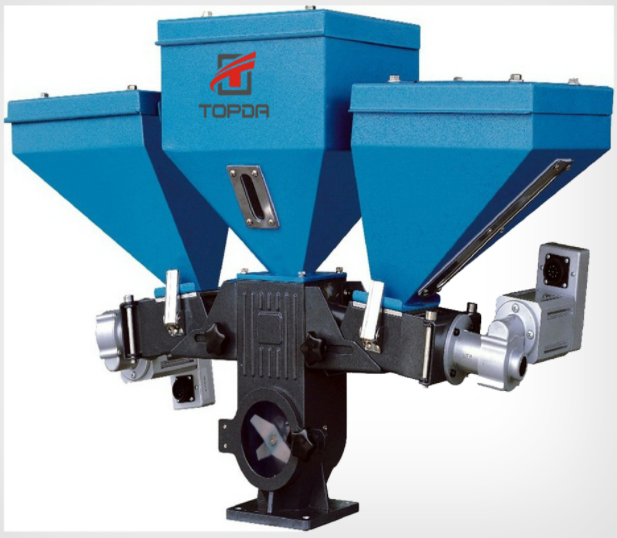

The Crushing Reality Of Plastic recycling machine blade

Plastic crusher blade selection is a critical game-changer. The right blade can transform waste management, offering:

- 40% longer equipment life

- 30% improved processing efficiency

- Significant cost reductions

Choose Crusher Blade Material Breakdown

| Material | Durability | Cost | Best For |

|---|---|---|---|

| Carbon Tool Steel | Low | low | Soft plastics |

| SKD-11 Alloy | Extremely High | normal | High-purity plastics |

| DC53 Tool Steel | High | high | Mixed plastic types |

Crusher Blade Material difference in hardness :

The carbon steel blade is especially suitable for carving and is also easy to sharpen to its original sharpness. The regular carbon steel (Cr 0.3%; C 0.75%) has a hardness of HRC 55-57.Solving the Recycling Crusher Blade .

Vacuum Heat Treatment: SKD11 material typically undergoes vacuum heat treatment, with quenching temperatures exceeding 1000°C and commonly using low-temperature tempering (150-200°C). The hardness can reach HRC61

DC53 Tool Steel is higher hardness (62-64 HRc) than D2 after heat treatment. Twice the toughness of D2 with superior wear resistance.

Blade Selection Strategies

- Analyze Plastic Type

- PET Bottles: Straight-cut blades

- Fibrous Materials: Hooked designs

- Contaminated Waste: Specialized alloy blades

- Performance Metrics

- Crushing Force: 175-200 lbf recommended

- Blade Lifespan: Up to 6 years with premium materials

Manufacturing Advantages

Our cutting-edge solutions provide:

- Customized blade designs

- Precision engineering

- Sustainable recycling technologies

Internal Linking Opportunities For Plastic Crusher Blade

Explore our advanced solutions:

Conclusion: Your Recycling Plastic Crusher Blade Revolution Starts Here

By choosing the right blade material, you’re not just crushing plastic—you’re crushing environmental challenges.

Call to Action

Transform your recycling process today! Contact our experts for personalized blade solutions.